Training Services

MARK VI Operation and Maintenance

Course Duration: 5.0 Days

Course Outline:

Day 1

- Introduction Speedtronic Mark VI

- GE Gas Turbine Fundamentals and control basics.

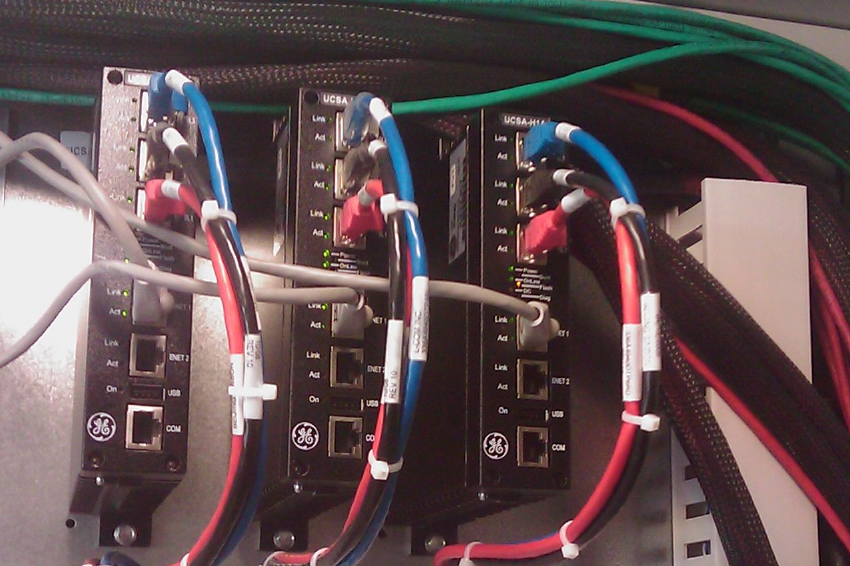

- System overview and Architecture

- Panel, modular concept discussion

- Mark VI cards

- Internal and external Mark VI wiring

- Hardware documentation

- The main protection system VPRO

- Supply voltage.

Day 2

- Data structure of the operator interface

- Brief discussion of the Windows 2000/XP based operator interface

- Most important files of the operator interface and their function

- Failure of the operator interface, what to do.

- Communications with the operator interface, Ethernet and DCS communications

- Operator interface facilities, TOOLBOX and Cimplicity

- Watch Windows

- The M6B file, functions, modules and tasks

- The Finder

- Trip log

- Alarm display

- Trouble shooting procedure

- Control constants

- Mark VI tools (TOOLBOX practice)

- Trend Recorder, Historical trip display, Alarms and SOE’s

Day 3

- Mark VI software structure

- M6B file, MKVI I/O and functions Programming languages of the Mark VI Macro’s and Modules

- Practice: Making Mark VI software with TOOLBOX

- Digital input.

- Analog input with software by students

- Digital input with software example by Students

- Gas turbine sequence

- Control modes

- Start up and permissive for start

- IGV sequence

- Normal stop

- Emergency stop

- Discussion of the following controls and sequencing

- Fuel control

- Start up, Speed, Acceleration, Temperature, Shut-down control and Manual FSR control Special control loops Inlet Guide Vane, Anti icing,

Water / steam injection and Start and stop. - Control loops The protection systems Flame detection, Overspeed, Vibration,

Exhaust temperature, Lube oil pressure and temperature, Fire protection system.

- Discussion of the following controls and sequencing

- Synchronization, auto and manual Power factor control MVAR control

- Dry Low NOx

- Explanation of the system

- Discussion of the controls, implementation in Mark VI

- controls and logics

Day 4

- Trouble shooting, alarm analysis and limited software changes in practice

- Diagnostics of card failure-Card replacement procedure.

- Alarm display-Setup and configuration

- Alarm Management (flow chart explanation)

- Exercise of different simulated alarms trouble shooting

- Changing control constants, adding alarms

- Trip Log display and interpretation.

Day 5

- Trouble shooting using simulation

- Configuring Trip log display

- Adding Sequencing (CI, CO etc.), Build, Downloading, HMI device

- Configuring a new Cimplicity screen.

- Case study: Unit “not ready to start”. Start Checks, Trip logs. First failure analyses for trips (emergency stop)

- Class Discussion and Evaluation of the course

Course Registration

Our Goal

Our goal is to provide our customers with the most up-to-date training available. Proper maintenance and training have been proven to be two factors which can guarantee a higher return. We at CTS can assist you in both areas. We provide our customers with on-site training which can be scheduled at your convenience. In addition, we are able to provide assistance with your maintenance/training plan to insure you get the kind of training you need.

Previous

Next