Training Services

GT Operations with Speedtronic (Mark V Controls)

Description: This customised course is designed to enable New Trainees/Graduates and on-site operators to understand the basics of GE Heavy Duty Gas Turbine features and how the Speedtronic Mark V control System governs the critical parameters.

The program will cover Gas Turbine Construction, support systems and the basics of GT controls and maintenance.

The course is designed to provide a solid background in turbine governing systems and Generator.

Participants increase their skills in relating machine operating requirements to the SPEEDTRONIC control.

Course Duration: 5.0 Days

Course Outline:

Gas Turbine Control Fundamentals

- Gas turbine principles of operation

- Governing System requirements

- Elementary Diagrams and Control

Introduction to Heavy Duty Gas Turbines

- GT Components

- Operating Systems

- Auxiliary Systems

- Video (Major Components of the Gas Turbine)

- Description of Piping Schematics

- 1. On-Base Fuel Gas System

- 2. On-Base Fuel Oil System

- 3. Lube Oil and Hydraulic Oil Systems

- 4. Cooling Water System

- 5. Cooling and Sealing Air

- 6. Diesel Starting Engine

- 7. Accessory Equipment

- 8. Air Inlet Filters

- Introduction to the Speedtronic Control System

- Instrument Field Devices and Device summary

- Introduction to Major Control Loops

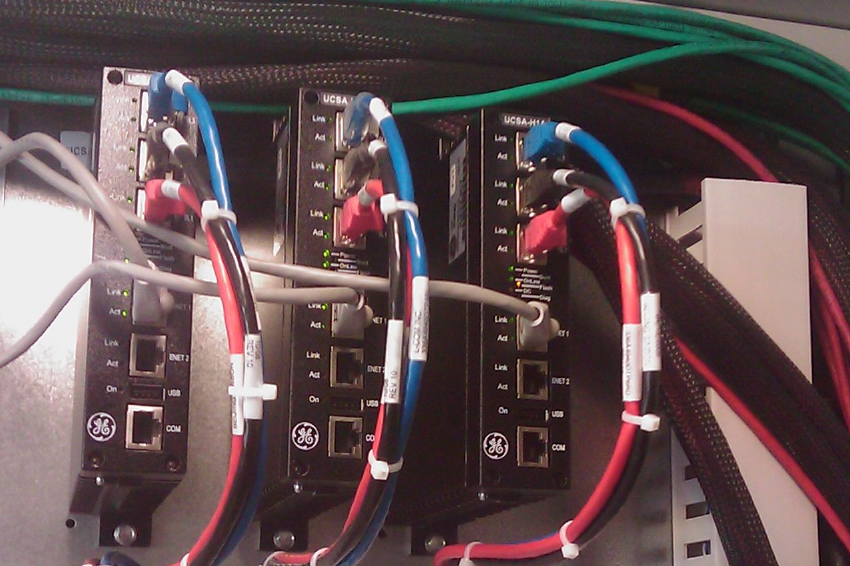

Mark V Panel Hardware

- 1. Panel Layout

- 2. Cores, I/O Cards, Terminal Boards

- 3. Basic Troubleshooting tools

Gas Turbine Control

- 1. Startup/Speed/Temperature/Acceleration Control loops

- 2. Protection Controls

Control Displays

- User Defined Display and Display programs

Software Tools

- 1. Difference between and HMI software

- 2. Data acquisition on Mark V interface

- 3. Animation displays (creating simple display)

- 4. How to interprete Sequencing using Dynamic Rung Display

Troubleshooting

- 1. Gas turbine process and Diagnostic Alarms

- 2. Easy approach to Mark V panel Systems Alarms

- 3. Using Rung Display for fault finding

Generator Control and Excitation

Synchronising and Loading

Course Registration

Our Goal